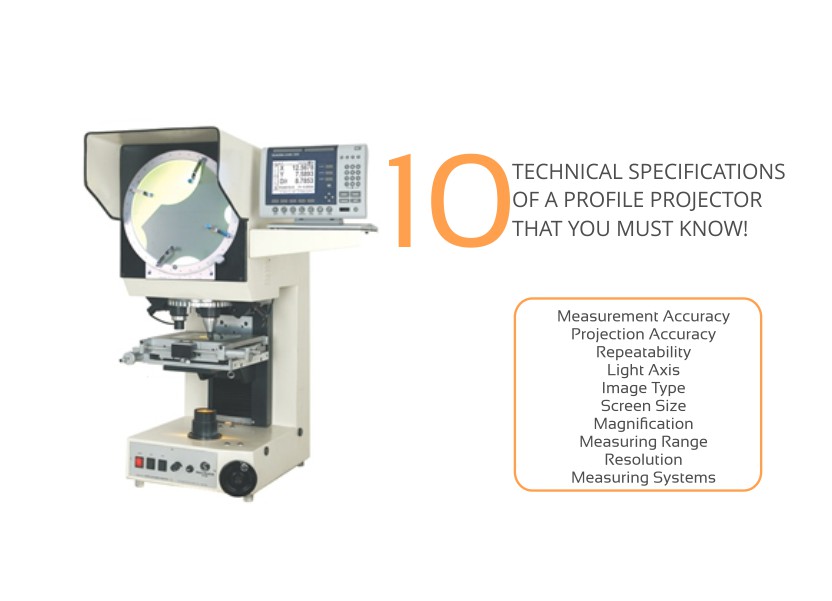

If you working in a manufacturing industry and planning to buy a profile projector or an engineering student wanting to know more about it, you need to understand its technical specifications so that you can choose the best suited model for your particular application. Below we have listed the twelve profile projector technical specifications that you should know.

Measurement Accuracy

The most important specification along with preciseness, described later, is the measurement accuracy. It is defined as the degree to which the result of the measurement conforms to the standard. Since we are measuring the part, the measurement results need to be as close to the real values as possible and the accuracy value defines how close we are to the real values. It has two components; the fixed component, which is inherent in the measuring system and the variable component which is dependent on the distance travelled.

Projection Accuracy

Since measurements are done on the projected image of the part instead of the part itself, it becomes very important that the projected image is precisely magnified by the optical system. It has two components: contour and surface for the namesake projections. A good optical system, with quality lenses & mirrors should have within +/- 0.05% projection accuracy.

Repeatability / Precision

It measures the closeness of the measured results of successive measurements. A system that is accurate but not precise is not reliable. It is very important that the Profile Projector gives same results for multiple measurements done on the same part. In an ideal solution the value should be zero, but in reality there are variations due to two causes. One is due to randomness and the other is due to some system fault.

Type

It refers to the orientation of the optical axis which can be either horizontal or vertical. The choice of light axis is not user specific but instead is defined by the load carrying capacity of the system. For heavy parts, a glass stage cannot be used and therefore the light axis has to be horizontal. On the other hand for light parts, the glass stage is feasible and so is the vertical light path.

Screen Size

This is the diameter of the screen on which the image is projected for measurements. It is usually made of ground glass with a centre cross-line etched onto it.

Image

Simple profile projector optical systems project image which is inverted and reversed. However if required additional optical elements are incorporated which give a non-inverted, non-reversed image.

Magnification

The part to be measured needs to be magnified so as to enable measurements. The magnifying power of the lens is specified under this category. The standard lens usually provided is 10X with 20X, 50X and 100X as optionals.

Lens Mount

If multiple magnification lens are provided they need to be arranged in such a way that so that they can be easily interchanged when required. A turret mount system allows for easy interchange by a simple rotation of the turret. The other method is screw mount, which is best suited when only one magnification is required.

Travel/Measuring Range

In a profile projector parts are measured by moving the workstage. This is the actual travel distance of the workstage and the linear glass scales. The X-Y measuring range will depend on the dimensions of the part that need to be measured.

Glass Scale Resolution

This is the least count of the glass scales that measure the X and Y distances. The user can choose from different options that the manufacturer provides which can be 5 microns/ 1 micron or 0.1 microns

Rotary Encoder Resolution

For profile projectors that need to measure angles this technical specification should be checked. The least count is usually 1 minute of arc.

Maximum Work Piece Height

A profile projector cannot measure heights. However since the space between the workstage and the magnification lens is limited, the manufacturer usually mentions this technical specification to convey the maximum height of the work piece that can be accommodated.

Measuring Systems

There are multiple options of measuring systems that the user can choose depending on his application. They are: micrometres, Simple DROs, Geometric DROs and Metrology Software.